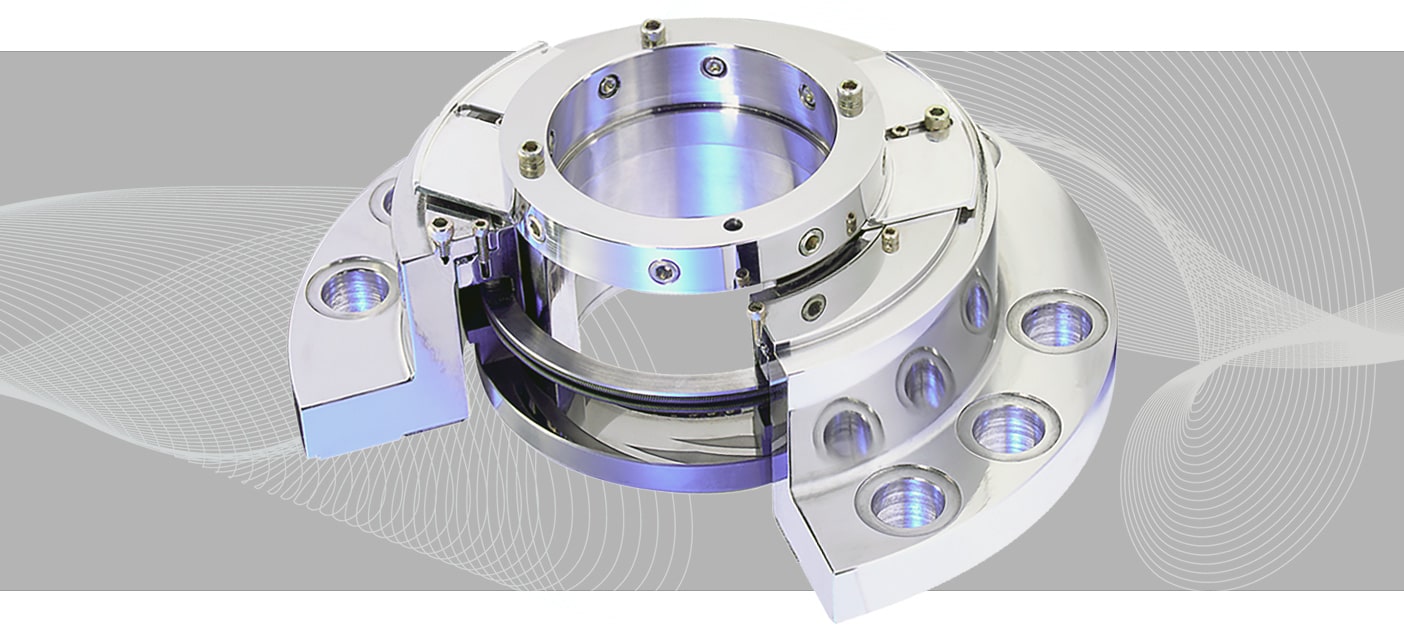

9 Tips for a Successful Wet-to-Dry Gas Seal Retrofit

Switching from a wet to dry gas seal is proven to enhance efficiency and reliability. Read our quick guide now for nine best practices to ensure your retrofit is a success, from identifying the ideal retrofit candidates to navigating challenges common in older compressors.

Explore the Sustainability Benefits of Our Wet-to-Dry Gas Seal Retrofit

Every day, mission-critical operators trust John Crane’s dry gas seals to curb emissions. View our guide now to join the growing number of customers who are enhancing sustainability and reliability through our Wet-to-Dry Gas Seal Retrofit.

Approximately 278,000 fewer tonnes of CO2 equivalent emissions per year

through John Crane’s Wet-to-Dry Gas Seal Retrofit

Shape Your New Energy Reality

John Crane delivers market-ready solutions with pioneering spirit, empowering our customers to shape their new energy reality today. Learn more about our vision for powering sustainability, which includes the critical challenge of curbing greenhouse gas (GHG) emissions.

Your Guide to a Streamlined, Successful Dry Gas Seal Retrofit

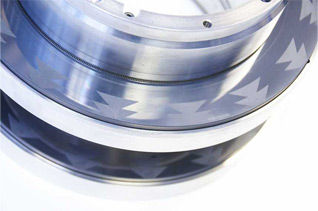

Many compressors in service today have been in operation for years, which can prevent them from reflecting the latest performance and environmental standards. Retrofitting these older units with up-to-date dry gas sealing technology can improve their operational performance, including reliability, longevity and productivity. It can also reduce a plant’s environmental footprint while significantly curbing emissions. However, it takes the right approach — and the right partner — to maximize the benefits of your retrofit.

Download our quick guide now to discover nine steps for a successful retrofit. In our eBook, you`ll discover the best practices for:

- Selecting the right retrofit candidates

- Compiling necessary technical information

- Determining the retrofit’s scope

- Finding an expert in dry gas seal technologies

- Aligning your retrofit with sustainability initiatives

- Verifying data before finalizing your design

- Maintaining old seals and systems

- Planning for turnarounds

- Navigating older compressors

Over the last 10 years, John Crane’s wet-to-dry gas seal upgrades have helped customers reduce approximately 278,000 tonnes of CO2 equivalent emissions per year. Read our guide now and contact our experts to accelerate your sustainability progress.

Discover the Benefits of Our Wet-to-Dry Gas Seal Retrofit

We help our customers through every step of the retrofit process, from conceptual studies to implementation, ensuring their transition to dry gas seals maximizes efficiency and reliability. Download our guide now for our nine-step approach to a successful retrofit.