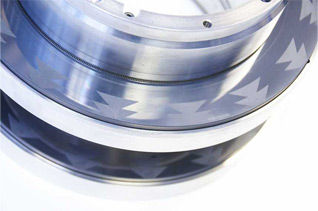

Emissions Reduced at Natural Gas Liquid Extraction Plant in the Middle East by Using John Crane Dry Gas Seals

Explore the Sustainability Benefits of Our Wet-to-Dry Gas Seal Retrofit

97% Reduction

in CO2 emissions by implementing dry gas seals

Shape Your New Energy Reality

John Crane delivers market-ready solutions with pioneering spirit, empowering our customers to shape their new energy reality today. Learn more about our vision for powering sustainability, which includes the critical challenge of curbing greenhouse gas (GHG) emissions.

A Case Study in Proven Emissions Reduction

An NGL extraction plant in the Middle East was searching for a way to lower emissions, increase reliability and safety, and extend the time between seal changes. Our experts retrofit the plant’s existing floating oil ring wet seals, installing dry gas seal technology on four centrifugal compressors. Download the case study now to explore how our solution helped the operator:

- Reduce its CO2 emissions by 97%

- Extend the time between seal changes from 3 to 5 years to more than 10

At John Crane, we are experts at engineering sealing solutions for challenging applications, including those presented by our client’s sCO2 power cycle plant. Read the full case study now and contact our experts for innovative solutions that accelerate your CCUS progress.

Discover How Our Retrofit Delivered Proven Environmental and Performance Benefits

Over the last 10 years, John Crane’s Wet-to-Dry Gas Retrofits have helped customers reduce approximately 278,000 tonnes of CO2 equivalent emissions per year. Download our case study now to learn more.