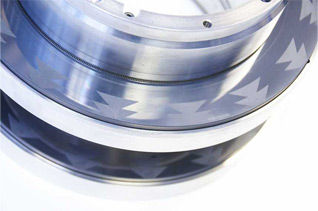

John Crane’s Dry Gas Seals Reduce Gas Emissions for Pipeline Station in the Middle East

When a pipeline station was seeking ways to curb emissions, it trusted John Crane to execute its wet-to-dry gas seal retrofit. Download the case study now to learn how our dry gas seal technology reduced the plant’s emissions by 98% — and completely eliminated process gas contamination.

Tackle the Methane Challenge With John Crane

Net Zero targets may seem out of reach, but John Crane is helping operators achieve measurable progress every day. Download our case study now for one customer’s experience with our emissions-reducing retrofit.

Millions of tonnes of methane and other greenhouse gases (GHG)

Prevented from being released into the atmosphere through our advanced methane sealing technologies

Shape Your New Energy Reality

John Crane delivers market-ready solutions with pioneering spirit, empowering our customers to shape their new energy reality today. Learn more about our vision for powering sustainability, which includes the critical challenge of curbing GHG emissions.

A Case Study in Measurable Emissions Reduction

A pipeline station in the Middle East had identified numerous priorities, including reducing overall emissions, decreasing machine maintenance costs and eliminating process gas contamination. To deliver these operational and environmental improvements, John Crane’s experts proposed a turnkey retrofit paired with a rotor dynamics analysis (RDA) to identify the source of the contamination.

Download the case study now to explore how John Crane’s wet-to-dry gas seal retrofit helped our client:

- Reduce emissions by 98%

- Reduce the turbine’s gas consumption by 2%

- Eliminate process gas contamination

- Reduce maintenance, energy and oil removal costs significantly

- Enhance compressor reliability

- Increase seal life from three to five years to 10 years

Over the last 10 years, John Crane’s wet-to-dry upgrades have helped customers reduce approximately 278,000 tonnes of CO2 equivalent emissions per year. Read our full case study now and contact our experts to accelerate your emissions reduction.

Discover the Benefits of Our Wet-to-Dry Gas Seal Retrofit

We help our customers through every step of the retrofit process, from conceptual studies to implementation, ensuring their transition to dry gas seals maximizes efficiency and reliability. Download our case study now to discover how one operator achieved its sustainability and operational goals with John Crane.